A team of engineering students at UW-Stout designed an innovative nonstandard pallet stacker for Arcadia-based Ashley Furniture, which plans to quickly implement the machine in its facilities.

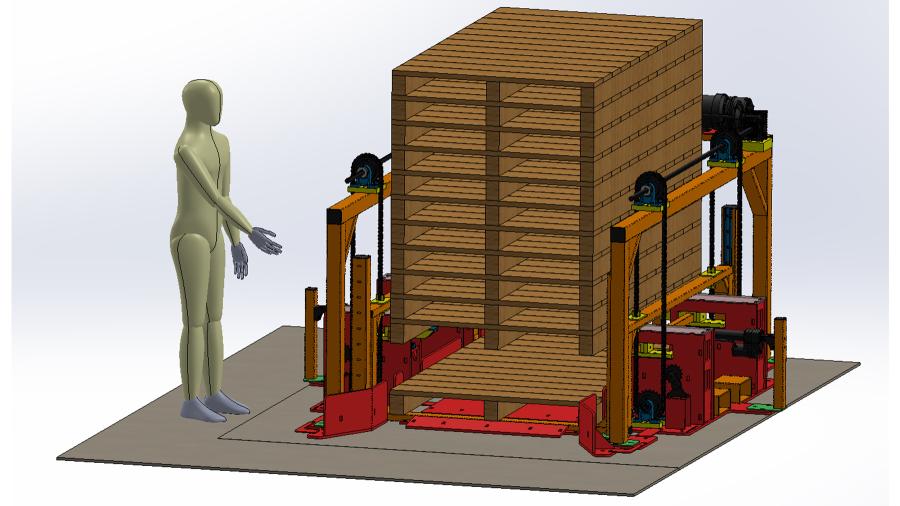

Within their Senior Design Experience II capstone course, the team was tasked with building a machine that could lift and hold 6-foot-long, 100-pound pallets off the ground until a stack of 12 was collected. Made of quarter-inch steel, the stacker can support 1,800 pounds, a 125% increase of Ashley’s requested 1,400 maximum stack weight.

Once the stack is complete, the system lowers it to the floor for removal with an electric pallet jack. The stacker – which is 10 feet long, 8 feet wide and 4 feet tall – can be operated by a single person and has a maximum cycle time of 40 seconds.

The student team is Luke Mertens, a double major in manufacturing and mechanical engineering from Blue Earth, Minnesota; manufacturing engineering major Zachary Morgan of Eau Claire; and mechanical engineering majors Chase Rodewald of Lake City, Minnesota, and Riley Stiehl of Alma.

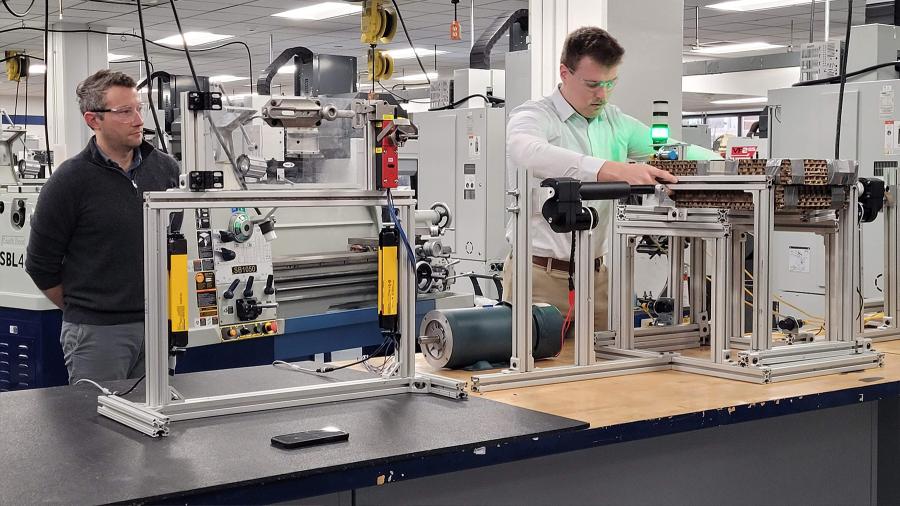

During the Manufacturing Engineering & Mechanical Engineering Showcase on Dec. 16, they presented a scaled, controls-focused prototype to UW-Stout faculty and supporters, as well as Ashley representatives, including Manufacturing Engineer Erik Kramer, the team’s project manager.

“The UW-Stout team built a better system, a better product for us. And with a final product price of about $25,000, their solution offers us a cost reduction of about 60%,” Kramer said. “Now, with the team’s documentation, our automation team can replicate their functional design to build six more stackers for our facilities.”

The team will submit their accompanying documents and the full-size machine, which includes an emergency stop for user safety, to Ashley for integration into the company’s operations. Final assembly will be completed at Ashley, when safety curtains will be installed around the machine as well.

Reverse-engineering to build a better product

The two-semester-long project began last spring, when the team had a site visit to Ashley to meet with Kramer and other staff. Ashley had purchased a stacker from a third party, but there were aspects of the machine that Kramer and staff didn’t like.

“We needed the Stout team to find a way to reverse-engineer the machine to have it function as we needed it to,” Kramer said.

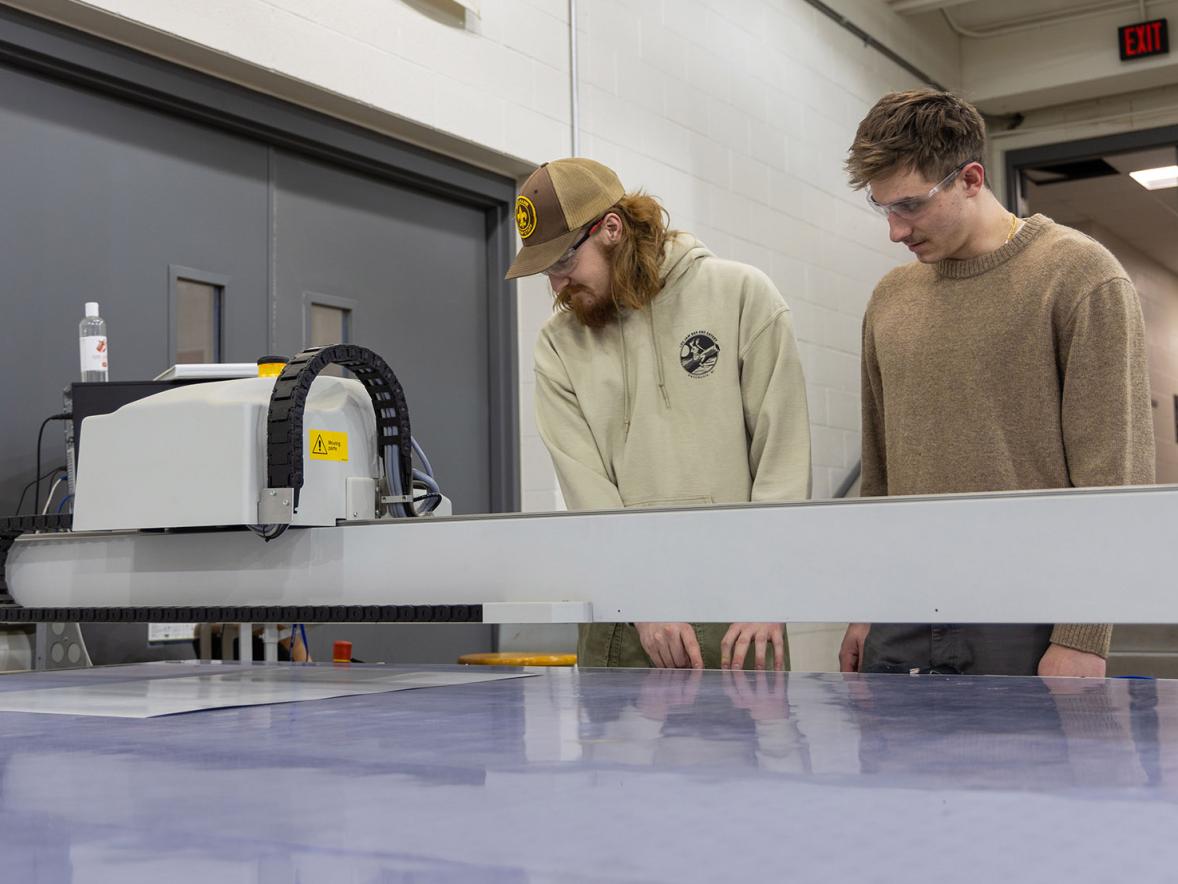

The team developed schematics in SolidWorks software and a small-scale model, which they presented to Ashley in May. Ashley purchased the materials needed to build the prototype as well as the final product.

“We’re no different than a real engineering team. Everyone is working together, but we each have niche roles based on our strengths,” said Mertens, who led the team’s controls and instrumentation. Morgan was the CNC machinist and completed the documentation and organization of project records. Rodewald and Stiehl managed the manual assembly, machining and welding.

While some of the parts were cut and machined at Ashley, the team also completed the machining and welding of parts in UW-Stout’s Fryklund Hall labs.

“There’s a lot to be done, so it’s nice to have multiple people working on it together,” Stiehl said. “We relied on Ashley’s industry equipment and experience. Having them cut and machine parts, rather than going to a third source, was a lot more cost-effective and saved a lot of time. And we could also use our own skills right in the labs on campus.”

Electrical and welding breakthroughs

During the first phase of their project, the team’s biggest challenge was how to meet one of the requirements set by Ashley: using electrical power, rather than pneumatics or hydraulics, to lift the pallets.

“Because most electrical motors are rotational based, it limits your options for linear motion, or the straight-line and up-and-down motion we needed for the pallet stacker,” Rodewald said. “We achieved this through a linear actuator, which is a device that converts a motor’s rotational energy into linear motion.”

The electrical power matches Ashley’s capabilities and can be implemented immediately on the shop floor by pulling in power from overhead sources, instead of the company having to install tanks to support a fluid power device.

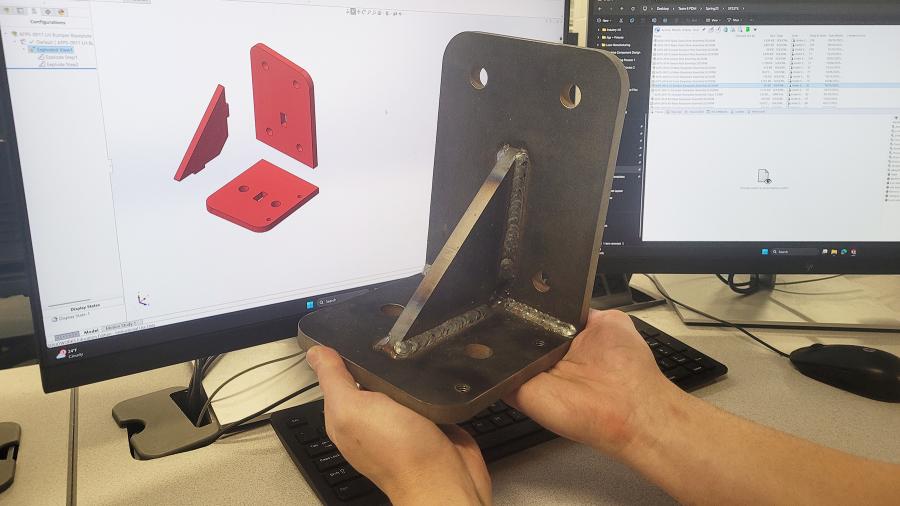

During the project’s second phase, the team was challenged by how to weld some of the individual pieces before final assembly. The gussets – a three-part support structure, for example – needed to self-align at a 90-degree-angle to make it easier for Rodewald and Stiehl when welding the pieces together.

“We devised a self-aligning slot and tab mechanism, so the parts would basically hold themselves in place,” Stiehl said.

“Breakthroughs often come just after the moment you feel you’ve exhausted every option,” Mertens added.

Engineering students use a project management methodology called a “stage gate process,” which includes built-in briefs and reviews at key points in the design and build process. It also allows for feedback from their classmates, professors and project sponsors.

“The process is very helpful because it allows you to review the current aspects of your design, so you never get too far down a rabbit hole,” Mertens said. “The feedback allows for a varying array of perspectives from your rough draft to the final draft of your concept.”

This fall semester, the Ashley capstone team was just one of a dozen teams composed of about 50 engineering students working on Capstone I and II projects in Fryklund Hall labs.

Mertens, Morgan, Rodewald and Stiehl earned their degrees and crossed the commencement stage on Dec. 20, among a class of 527 Stout Proud graduates.

According to the university’s most recent First Destination Report, 99% of 2023-24 graduates from the mechanical and manufacturing engineering programs reported they were either employed or continuing their education within six months, with an average starting salary of $72,000.

UW-Stout’s Robert F. Cervenka School of Engineering is home to five ABET-accredited programs that also include computer and electrical engineering, engineering technology and plastics engineering, as well as a sixth bachelor’s program in packaging. A master’s in manufacturing engineering is available on campus or online.