In University of Wisconsin-Stout’s Plastics Lab, students banter about their pet dogs as they collect data from a differential scanning calorimetry that measures the thermal properties of plastics.

Not that much different from a lab in years past. However, with COVID-19, the students aren’t able to be in the laboratory together because of social distancing requirements. But they are still learning experientially together, using computer remote control and virtual meetings, even though they may be miles apart.

“I enjoy that we each have been able to take our turn with controlling the programs we are running,” said plastics engineering major Heather Rinehart, a junior from Bloomer. When it is not our turn, we are still able to view and discuss the program our groupmate is inputting.”

One major difference is students can’t physically load the materials into the analyzers, Rinehart said. “If something doesn’t go right, we don’t have the ability to physically troubleshoot the problem,” Rinehart added.

“However, we are still able to see the troubleshooting process. It’s almost easier to see what our professor is doing because we aren’t trying to crowd around the equipment. Other than that, running the experiment with the computer is the same.”

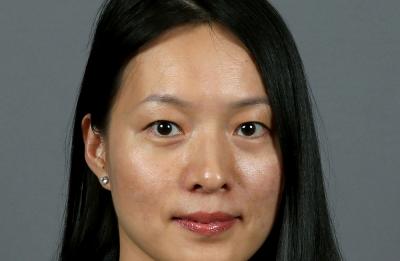

Wei Zheng, program director and associate professor, is teaching the class, Testing and Analysis of Plastics, which has 19 students.

“The limited physical space we have in the testing area does not allow the class to practice safe social distance,” Zheng said.

During the four-hour lab students divide into groups and use four types of equipment to characterize the physical, mechanical and thermal properties of various plastics.

Students design the program, conduct their tests and collect and analyze the data through remote control of computers operating the equipment, Zheng said.

The whole process is operated virtually over the Microsoft Teams platform, where students discuss their experiments, share results and ask questions. “Ninety percent of what they are doing is exactly what they would be doing if they were physically in the lab,” Zheng said.

“The only difference is that the samples are loaded by me or the lab assistant, but the loading process is live streaming to the students and discussed with them, especially when something goes wrong.”

In the course’s labs, in addition to measuring the thermal properties of plastics, students use a:

- Thermogravimetric analyzer to study the degradation of polymers

- Rheometer to measure the viscoelasticity of plastics materials

- Fourier-transform infrared spectroscopy to determine the chemical structures of plastics

- Dynamic mechanical analyzer

- MTS mechanical testing system with, tensile, compression and flexural geometries to determine the stress-strain behavior of plastics.

“The course also teaches students about plastics failures and how to reduce/prevent them,” Zheng said.

Olivia Hile, a lab assistant and a sophomore majoring in plastics engineering, said, “Wei is still encouraging collaboration and group efforts. Even though the students are not physically with each other, they still have good communication and are working as teams as far as I can tell.”

Hile, of Rice Lake, chose UW-Stout for plastics engineering after visiting campus and meeting Zheng. The environmental and necessity of plastics engineering attracted her to the major.

“Yes, we always hear about how bad plastics are for the environment, but that is a problem people need to fix,” she said. “The energy savings of using plastics over glass or metals is extremely high both in production and transportation. At the end of the day, we are never going to stop using plastics, so I want to get into the industry to try and improve the process and make less waste.”

Rinehart said she decided to major in plastics engineering because it encompasses mathematics, chemistry and has a creativity factor.

She appreciates how Zheng has worked to adjust the labs because of COVID-19 and the social distancing requirement. “While we would love to be in the normal classroom setting, UW-Stout is trying to provide an experience as close to that as possible.”

Zheng said she believes having virtual labs will become the norm, continuing after the pandemic ends.

“I see a lot more use of remote control learning in the future,” she said. “In online courses of students who are working in industry, this is a great way to explore and learn experientially.”

The remote classes would offer greater flexibility for a broad range of student populations, especially for those who are unable to attend an in-person class.

“We are thinking about offering technical trainings to companies,” Zheng said. “They would still be able to enjoy a learning environment.”

Highly ranked program

UW-Stout has been named one of the top U.S. public colleges offering plastics engineering programs by Plastics Today, a publication and site for plastics professionals. UW-Stout is one of eight universities noted in the article for polymer/plastics engineering programs.

The university also was ranked No. 7 of 11 schools by stateuniversity.com as most popular for polymer and plastics engineering majors.

Along with plastics engineering, UW-Stout offers bachelor’s degrees in computer and electrical engineering, engineering technology, manufacturing engineering, mechanical engineering and packaging.