A $3.1 million donation of high-tech equipment from the Ronald and Joyce Wanek Foundation (the Foundation) will dramatically increase University of Wisconsin-Stout’s ability to offer a state-of-the-art polytechnic experience for students in design, engineering and education programs.

The generous gift of equipment – which includes production-level 3D printers, a fully-integrated automated manufacturing system and more – is the result of an ongoing partnership between UW-Stout and the Wanek family and their business, Ashley Furniture Industries, based in Arcadia.

“We are extremely grateful for the generosity of the Ronald and Joyce Wanek Foundation and its belief in the distinctiveness, relevance, and need for the polytechnic learning experience that UW-Stout provides,” UW-Stout Chancellor Katherine Frank said. “This investment in labs and high-demand programs will serve thousands of students prepared to enter the workforce and contribute to the economic vitality of Wisconsin and beyond. The strong relationships with our business and industry partners, like Ashley Furniture Industries, are key to our ability to produce UW-Stout graduates prepared to succeed on day one and throughout their professional career.”

The Ronald and Joyce Wanek Foundation is a philanthropic organization committed to supporting STEM (science, technology, engineering and math) education and other community initiatives. The Foundation was established by Ronald Wanek, founder and chairman of Ashley Furniture Industries, LLC, and his wife, Joyce. Their son, Todd Wanek, is a 1988 UW-Stout alum and president and CEO of the company.

“Our partnership with UW-Stout represents a strategic investment in the future of STEM education,” stated Ron Wanek, founder and chairman of Ashley Furniture Industries. “By providing students with access to industry-standard equipment and technology, we are ensuring they graduate with the practical skills and technical expertise that today’s employers require. UW-Stout’s polytechnic mission aligns with our commitment to developing a skilled workforce, and we are pleased to support their efforts in preparing the next generation of manufacturing professionals.”

The Foundation’s investment expands applied learning across UW-Stout’s STEM disciplines, benefiting both undergraduate and graduate students as well as allowing them to gain additional industry certifications. It also will enhance experiences for K-12 students and professional learners, amplifying the impact of UW-Stout’s polytechnic focus.

Daniel Freedman, dean of the College of Science, Technology, Engineering, Mathematics and Management, said the new equipment will create automation, robotics and 3D printing labs at UW-Stout that will be in the top tier for undergraduate engineering programs in the United States.

“UW-Stout’s partnership with Ashley Furniture and the Foundation will make us a national leader in educating students and supporting the manufacturing community in digital design, digital fabrication, and digital assembly and production,” Freedman said.

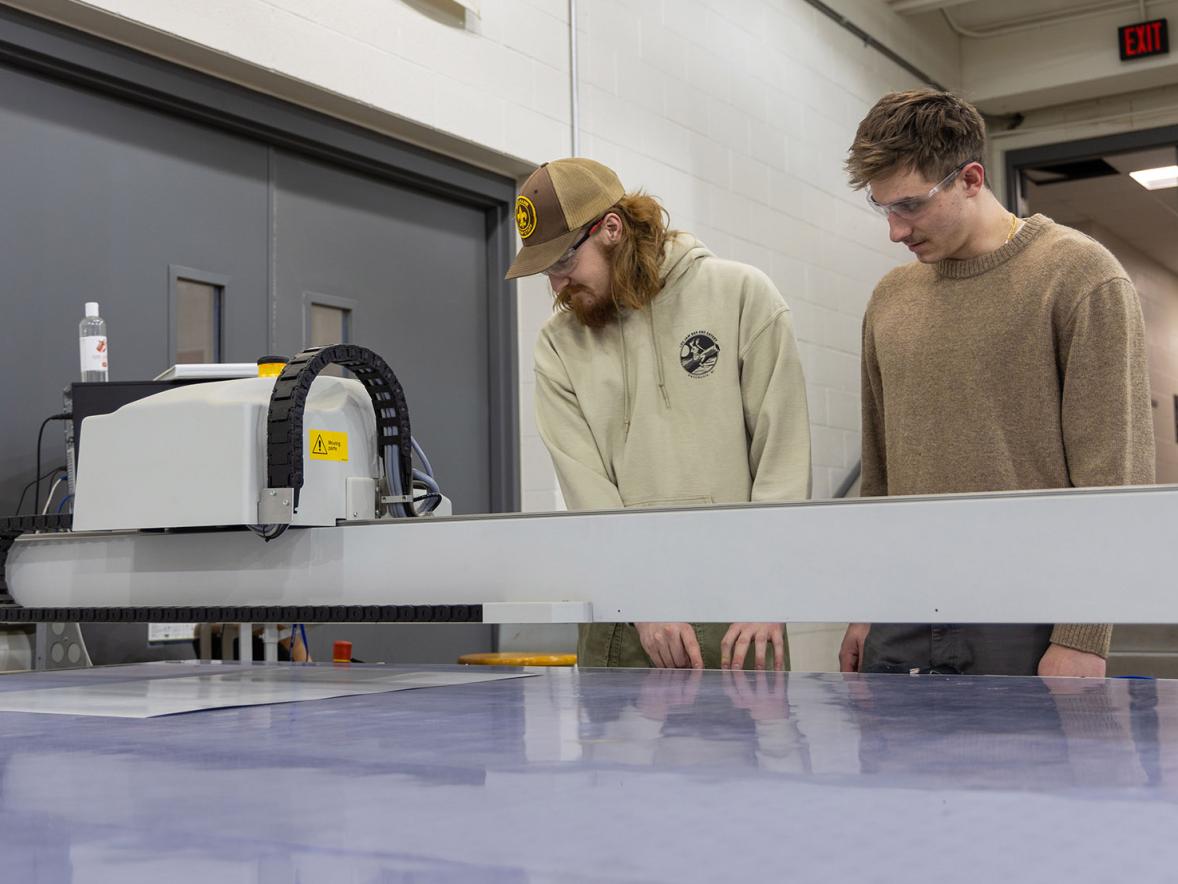

The equipment donated by the Foundation will be used in multiple campus locations, including three labs in Fryklund Hall and one in the Jarvis Hall Technology Wing. Some equipment has already been installed, while the rest will be put in place for use during the soon-to-begin fall semester, when it will be used by thousands of students in multiple programs.

The Foundation’s equipment donation includes the following:

- An Amatrol Smart Factory Enterprise system, which will be used to create a new Automation Training Center. This fully integrated automated manufacturing system includes a manufacturing line composed of processes such as inventory control, inspection, sorting, assembly, testing, CNC machining and storage, all linked by ethernet or wireless communications. The system is designed to showcase how all these technologies are integrated in a modern production system and to educate students in how to build and maintain these systems. Through the Smart Factory Enterprise system and UW-Stout’s ground-breaking Automation Leadership and Engineering programs, the university will be able to offer a wide variety of industry recognized certifications through the Smart Automation Certification Alliance (SACA).

- Three new Universal Cobots (collaborative robots) and six AI-powered Cognex Vision Cameras will be added to UW-Stout’s already impressive Industrial Robotics and Machine Vision Lab. AI powered robotics creates a major leap forward from preprogrammed automation to intelligent, adaptive systems. Adding AI turns robots from rigid machines into smart collaborators that can see, learn, adapt and optimize – making them far more valuable in manufacturing, healthcare, logistics, agriculture and beyond.

- UW-Stout’s Additive Manufacturing Lab will be upgraded with state-of-the-art industrial printers. This includes a One-Click metal printer and Origin II, J55 and H350 printers from Stratasys, enabling the printing of almost anything out of a wide variety of materials, from stainless steel to nylon to high-performance plastics such as ULTEM and Antero. The Origin II and H350 are production-level 3D printers that will fabricate tens to hundreds of parts virtually overnight at high resolution and precision.

- The Fryklund 101 machining lab has been upgraded with 6 Haas VF-2SS CNC mills; a Haas ST-20Y CNC lathe with Y-axis capabilities; a bar feeder and live tooling; and a Fanuc Robodrill with a machine tending robot system. Two of the Haas CNC mills will be fitted with machine tending robotic systems from Universal Robots and Robotiq end-of-arm tooling.

This new equipment will enhance the education of well over 1,000 students and will support UW-Stout’s many industry partners by giving them access to advanced technology directly and through student projects as well as opportunities for upskilling employees in automation and additive manufacturing.

“The equipment provided through this generous donation will create valuable hands-on learning opportunities for a wide range of students – including those in engineering, engineering technology, technology education and business programs, particularly those focused on automation leadership. In addition to enhancing student learning, the equipment will support workforce development initiatives and serve as a resource/platform for funded research projects sponsored by industry partners and external agencies,” said Professor David Ding, director of the Robert F. Cervenka School of Engineering and associate dean of CSTEMM. “Bringing this equipment into our labs is not the final step – it marks the beginning of our continued commitment to elevating the UW-Stout learning experience to a new level.”

Previous collaborations between the university and Ashley Furniture include a cross-disciplinary student project to develop toolless bed connections and the company’s sponsorship of engineering students’ capstone projects. In addition, Todd Wanek was UW-Stout’s Cabot Executive in Residence in 2017.